Tag Archives for " telematics "

Does your supplier own your data, or do you?

The world is getting more and more connected. I’m connected to my car, my kid’s watch, and my doorbell. If I were to buy a new tractor, loader, or trencher, I’d expect to be connected to that too.

For equipment manufacturers considering their connected strategy, there are two approaches. We’re going to talk a bit about each of those approaches, in general I’m an advocate of the Open approach which is described below.

Open and Closed Approaches

At a really high level, there are two approaches to making equipment connectivity happen. Closed and Open.

The Closed approach is an approach where a supplier brings a full system and solution for connectivity. This includes the onboard telematic unit, the backend/cloud service, and the mobile/web experience. This is attractive because it is an easy button, one stop shop, for connecting a machine. The downside is that you are no longer in control of your data, your customer’s data, and you’re going to rely on the permissions granted by a supplier for information that is increasingly critical to your business. They say data is the new oil, you’ve given your supplier your mineral rights.

The Open approach is an approach where a supplier brings an open system for a telematic controller or asset tracker. This means that you can change the software on the system (either internally or with contract resources). This typically means that you need to develop your own backend/cloud service and mobile/web experience. Undoubtedly, this is harder and requires more effort than a turn-key supplier-delivered approach. As they say, nothing worthwhile is ever easy and we’ll discuss the upside below, but the key is that you control your data, how it is used, and can direct the path of value added services that are built off this data. This data, this digital oil, is incredibly valuable in so many ways.

Control of Data

Before discussing data and value propositions, it is important to understand that to achieve these value propositions you must control the data. There are different perspectives on data ownership. Some people believe that the operator should control the data. Others contend that the ownership of the data should reside with the equipment manufacturers. In any event, your supplier should not own or control your data. It is simply too valuable to have to ask for permission to access, to modify, and to mine.

Decreased Costs

Access to this data provides opportunities for the reduction in costs or avoidance of expenses. These cost reductions come in a number of different packages. Having data about the fleet and its operation can lead to value added services that improve fleet safety, which limits litigation and settlement expenses with a reduction in incidents and accidents. This data can also be used to provide the evidence necessary to negotiate with insurance carriers, providing critical information necessary to manage this growing industry expense. Lastly, the data can be used to understand the circumstances related to warranty claims which can lead to the avoidance of payment on unjust claims and the improvement of design to eliminate future claims in related areas.

Increased Revenue

Control over the data creates potential for delivery of value-added services to customers, which creates potential for new streams of revenue. Such services can include things like web-based analytics that allow for more productive utilization of fleet assets and leveraging data to efficiently schedule and use expected machine downtime for maintenance. Interesting opportunities can also emerge in the monetization of third-party, value-added, services through APIs that allow selective access to your data. In these cases, a programmatic interface is created to allow additional companies to access data, at the customer’s request, to provide more niche services at high value. The access to that data can be monetized, with a fee charged to the third party, giving you a portion of their revenue stream without any of the development or maintenance burden of the niche application.

Expansion Potential

Whenever one of our customers really starts to dig into their data, two things emerge. The first is value. The second is more questions that, if answered, are expected to uncover additional exciting business value.

This is where an open platform is also critical. Answering those questions can involve changes to the software on the telematic unit, changes to the backend architecture to mine/compare/contrast data in different ways, or changes to the mobile experience to better present customer features or track customer behaviors. In this way, the cycle of data acquisition, analysis, and value creation becomes an evergreen – but only if you have the control necessary to drive the evolution of your connected ecosystem. This only happens in an open platform.

Flexibility

We believe you should have the freedom to choose. You should be free to choose which telematic supplier you select for different equipment platforms. You should be free to choose which mobile devices are compatible with your solution. In an open system, you are free to specify, implement, and manage these choices. A constraint of a closed system is that you’re locked into the offerings, and mobile device support, from a single supplier. That supplier may be great, but then you’re also locked into the timelines associated with which that supplier supports new generations of connectivity technology (4G, 5G, etc) as well as the timeliness which with that supplier can offer you access to connectivity services in new countries.

Control of Security

Open doesn’t mean unsecure. Open means having the freedom to impose your cyber rules and requirements on the system, ensuring that your security preferences are embodied in your connected solution. When you own your security you have the comfort of certainty. When you’re working in a closed party system, there are always questions about the security and control of access to your equipment, your data, and your customer’s data.

David Batcheller

President & CBOhttps://appareo.com/2021/03/23/does-your-supplier-own-your-data-or-do-you-2/

Bell Certifies Appareo Device for New Helicopter Flight Data Monitoring Program

Appareo’s Aircraft Communication Units (ACUs) are highly-capable, well-connected mobile computers for a broad range of aircraft types

Earlier this month, Bell Textron Inc. announced the Supplemental Type Certificate (STC) for the installation of an Appareo-developed aircraft communication unit (ACU), which is the on-aircraft component of the Bell QuantiFLY system. Currently available for the Bell 407GXi and Bell 429, QuantiFLY was developed to enable Bell operators to be actionable and drive safety through an affordable, lightweight, and fully automatic flight data monitoring (FDM) solution.

“Bell selected Appareo Systems for connectivity hardware based on its proven track record for both world-wide cellular telematics and aircraft data monitoring. The device utilizes cellular (4G LTE / 3G GSM) on the ground data transmission to offboard aircraft flight parameters and maintenance data via cloud for processing and analytics.” – Bell news release

“Throughout our relationship with Bell, we have witnessed their commitment to provide Bell customers with innovative technology to enhance the safety of their operations and improve their flight experience,” said David Batcheller, President & CBO of Appareo. “Appareo was pleased to partner with Bell on the development of the hardware solution for their new FDM service, and we’re excited that the newly STC’d QuantiFLY is ready to deliver actionable data to Bell customers.”

Appareo’s line of ACUs are lightweight computing and communications devices that function as a data acquisition system for FDM or flight operations quality assurance (FOQA) programs for fleet operators, or as a telematic and connectivity product for airframe manufacturers. Find full product specifications here, or contact Appareo for information about pricing.

https://www.appareo.com/2021/01/28/bell-certifies-appareo-device-for-new-helicopter-flight-data-monitoring-program/

Appareo Releases New Open Platform Telematics Device with Truly Global Connectivity

NEWS RELEASE

Appareo Releases New Open Platform Telematics Device with Truly Global Connectivity

The IP67-rated Gateway 370 features Iridium® SBD, 4G/3G/2G, and eSIM, certified for use in the USA, Canada, Europe, Brazil, and more.

FARGO, North Dakota (January 21, 2021) — Appareo today released a new product in the company’s award-winning line of telematic control units (TCUs). The Gateway 370 is a rugged yet lightweight edge computing platform for mobile equipment applications that provides a wide range of communication technologies. This release builds on the Gateway 270 model that was launched in 2020, adding an Iridium short burst data (SBD) satellite transceiver for truly global communication capabilities, and a 433 MHz receiver for use with sensors and active RFID tags.

Gateway 370 is built on an open and flexible platform that supports standard programming languages and tools, allowing Appareo customers to quickly and easily develop their own applications on the hardware. The device is built on a popular distribution of embedded Linux (Yocto) with Docker support, allowing a convenient development environment for C++, C#, or other common development languages.

“This flexibility and approachability gives Appareo customers the control they desire — allowing them to use a variety of approaches and resources to achieve the maintenance, service, and operational benefits customized to their needs,” said David Batcheller, President & CBO of Appareo.

In addition to the satellite and 433 MHz radios, the Gateway 370 comes with the full set of features found in the Gateway 270 model, including global LTE CAT 4 cellular radio with 3G/2G fallback and eSIM; dual core processor for handling significant computational capabilities at the edge; Wi-Fi and Bluetooth interfaces for communication between mobile devices and the machine for control and/or monitoring purposes; 6x CAN bus interfaces; Ethernet; BroadR-Reach; RS-232; GPS; and more.

These capabilities are housed in an IP67-rated rugged enclosure for use outdoors and for mounting on construction and agricultural machinery. The device’s array of wired and wireless communication technologies make it well suited for a broad spectrum of equipment control, monitoring, and connectivity challenges.

Wide Area Network

The Gateway 370 is certified for deployment in a broad range of North American, South American, and European markets, making it ideal for equipment manufacturers with broad geographic distribution. Appareo worked with carrier partners Vodafone International and Tata Communications to maximize the geographic potential of the Gateway 370. However, cellular coverage is still limited in some geographies. Appareo’s inclusion of an Iridium transceiver in Gateway 370 ensures that Appareo customers stay connected with their machines and that critical machine data can be retrieved, wherever that equipment may be (land, air, or water).

Local Area Network

The LAN connections (Wi-Fi, Bluetooth, and 433 MHz) allow machines to communicate directly with each other and with the operators or passengers. For example, people near the machine can be connected, informed, or in control, using real-time data with zero latency and no network costs. Further, the Gateway 370 can communicate with active RFID products (e.g., asset trackers), tire pressure sensors, and other wireless machine sensors. This capability allows for machines to receive information from hydraulic and mechanical attachments, and despite the lack of electrical power on those attachments, use information from the active RFID tag to recognize the attachment, and automatically adjust machine control settings accordingly.

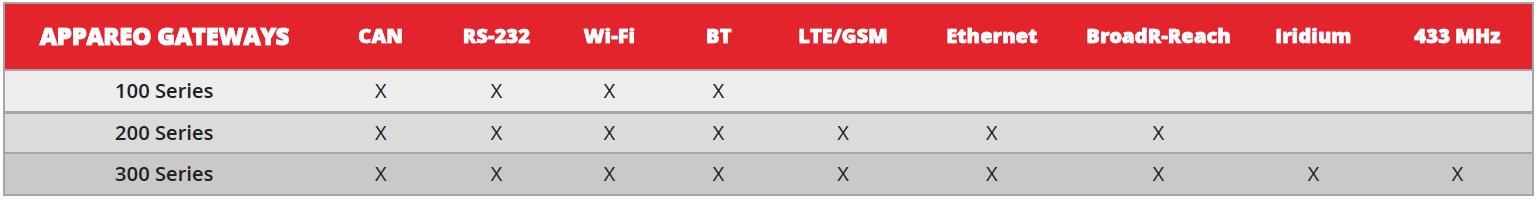

For applications where Iridium is not required and the application may be more cost sensitive, defeatured variants of the Gateway telematic control units are available with the same open platform principle. This family design approach allows Appareo customers to access and utilize a variety of TCUs, on the same open platform, with a variety of capabilities and price points to address specific needs.

Appareo Gateway Series

To contact Appareo, acquire a development kit, and begin working with Appareo Gateways, visit appareo.com/gateways.

# # #

About Appareo

Appareo is a recognized leader in the custom design, development and manufacture of innovative electronic and software solutions for aerospace and terrestrial applications. Through the creative application of cutting-edge technologies, Appareo creates complex end-to-end solutions that include both mobile and cloud-based components. The company is privately held, with headquarters in Fargo, N.D., and a design office in Paris, France. All products are built and supported in the USA.

Product Photos: appareo.com/media

https://www.appareo.com/2021/01/21/appareo-releases-new-open-platform-telematics-device-with-truly-global-connectivity/

Configuring Wake Modes to Maximize Battery Life in Cellular Asset Trackers

Operators want to use their expensive machines (loaders, sprayers, excavators, aircraft, etc.) as much as possible, because at the end of the day, business assets are more of an asset when they’re put to work. When a fleet is distributed over a large area, knowing where equipment is so it can be put to work can be a challenge.

Over the last decade, it has become common for larger or more expensive equipment to be delivered from the original equipment manufacturer (OEM) with a telematics standard. Sometimes it’s a simple position reporting modem, other times there’s a huge volume of operating detail being delivered to the cloud. In any event, it makes it much easier for operators to start tracking a fleet of assets when the equipment comes standard with tracking capability.

The challenge

There are still holes when trying to conduct an efficient operation with a full picture of the fleet. These holes exist because many fleets have equipment that did not come with factory telematics.

For example:

- Tenders, dump trucks, and other Milk Run equipment that create the maximum productivity of a working asset also typically do not have stock telematics

- Specialized equipment produced in lower volumes by smaller OEMs, and therefore not factory-equipped with tracking features

- Towed equipment that is not electrified (e.g. trailers, carts, screens, mowers, balers, tedders, rakes, grinders, chippers, etc.) and as a result have no built-in tracking connectivity

- Expensive attachments that are unpowered

- Older equipment that is in good working order but was delivered before connectivity was standard among major OEMs

Considering these holes, you may only be able to track a portion of the fleet. Even if it’s 75%, it’s not good enough. A project can’t happen if only 75% of the equipment is at the site. That makes these holes important to fill, but it also has to be easy. Operators don’t have the time or the interest to assemble a pile of dissimilar aftermarket technology offerings into a fleet tracking solution — they have a business to run.

The good news

In a previous blog (Understanding 4G LTE Categories) we discussed new kinds of cellular technology that have emerged as a portion of 4G offerings. These technologies, specifically NB-IoT and M1, create opportunities for very rugged and affordable “slap and track” cellular asset trackers. These kinds of trackers can be attached to any piece of equipment, and by using their own battery they can report its location for years.

![]()

This can be an easy fix to the problem, but getting real satisfaction out of these solutions is all about managing the battery life of the unit. Why?

- Many rugged asset trackers are made without replaceable batteries in order to achieve an IP67 or IP69K rating. Although these trackers are cheap, they need to be discarded when the battery is used up.

- Trackers with replaceable batteries lose the “easy fix” appeal once you’re spending time tracking down machines to charge their units or replace batteries. The appeal of this solution is ruined if you can’t leave a machine alone for at least a season — ideally for the life of the machine.

So, how do you use “slap and track” solutions to the maximum benefit of your business? I know people hate this answer, but it depends. As you consider your equipment tracking goals, it’s important to understand battery life and wake modes.

Understanding battery life in cellular asset trackers

Battery life is fixed, meaning you start with a bucket of energy and that is all you get. Therefore, to achieve maximum customer value, the focus needs to be about extending the duration of time that a rugged asset tracker can be used.

To maximize that energy:

- Devices need to be off as much as possible

- When on, devices should sparingly use the components that use a lot of energy (e.g. cellular and GPS)

Device manufacturers have put a bunch of battery management tools into these devices, and the asset tracking ecosystem, to make tracking as easy as possible. It varies by manufacturer, but when a device is advertised to have a 5-year lifetime, that’s typically based on an expectation of a few thousand positional reports over its lifetime. That works out to 1-2 position reports per day for five years. So, while the device’s lifetime is marketed in the form of years, in reality the lifetime is based on the number of positional reports utilized.

Understanding how different wake mode configurations affect battery life

Making the most of the battery management tools should get careful consideration as you deploy trackers. We recommend consulting with your tracking services or hardware supplier to dial this in as early as possible. Devices can typically be configured to report in the following ways (organized from most power hungry to least power hungry):

Periodic continuous reporting

For trackers that are integrated into the machine and connected to vehicle power, this is an easy and inexpensive thing to do. However, most customers with battery powered trackers will not want to use this mode. Having the device report every minute, or even every hour, will consume a lot of battery life.

Wake and report on movement

Many asset tracking devices include an accelerometer. These are great because they use minimal energy and can be used to wake the device when it moves. This is helpful if you want to know when equipment is moving from site to site or when equipment has begun working, for example. Depending on the tracker’s capabilities, it might be possible to set the device to report on movement but then to “snooze” for a period of time (e.g. 4 hours). A word of caution, however: if you can’t snooze its reporting behavior, this feature could run through the battery life quickly.

Wake and report on rest

This is related to the movement feature, but it notices when the device stops moving for a period of time (typically configurable) and then reports the device position. It’s an inverted version of the previous feature with the same benefits and challenges.

Start of day / end of day position reporting

This feature is generally easy to configure, easy to implement, and very friendly for battery life. Simply pick a time of day and have the unit report its position at that time every day. This can give you an overview as to where the equipment was left at the end of the day, giving you an opportunity to dispatch resources effectively at the start of the following workday. When combined cleverly with some of the above features (e.g. report equipment position at 5:00 PM, then report on movement in the event someone moves it after hours), it can be used to give an effective and timely overview of fleet positions while using minimal battery.

Wake on demand

This easy to use feature is very powerful and enabled by the newest generation of cellular technologies. For those of you who want to push your glasses a bit higher on your nose and nerd out with us about how this feature works, we’ll dig deeper in a future blog. For this post, we’ll talk about the capability at a high level so you can understand how to exploit it.

Using a computer or mobile device, you ask the equipment to report its location. This feature sends a message over the cellular network, which is stored in a mailbox of sorts. The device periodically checks that mailbox, using very limited energy, to see if it needs to report in. If there’s a request waiting, it reports its location.

The beauty of this feature is that whenever you need to know the location of an asset, you can have the device report in at the push of a button. The report doesn’t come back in seconds, because typically the device is configured to “check the mailbox” at scheduled intervals in order to minimize energy use. However, even waiting a few minutes to get the devices’ location is MUCH faster than driving from site to site looking for it.

Do you want future connectivity advice, insights, and information delivered to your door? Join our email list, and follow us on LinkedIn.

![]() David Batcheller – President & CBO

David Batcheller – President & CBO

https://www.appareo.com/2020/12/14/configuring-wake-modes-to-maximize-battery-life-in-cellular-asset-trackers/

8 Benefits of Using Tablets as Displays in Off-Highway and Industrial Machines

The trend is reversing for displays in off-road rugged equipment. Instead of incorporating lots of control logic into display systems, it’s going to become much simpler.

The preeminence of the display as a compute source on the machine, rather than a simple operator interface, was born more of convenience rather than an optimal machine control architecture. When more complex display terminals began to emerge on the market, many of those terminals were utilizing a Windows operating system. The hardware needed to host Windows was left with unutilized computing power. Many organizations, as a result, began taking advantage of that by putting machine control software into the terminal.

Today, however, significant computing potential is possible within embedded devices with a broad spectrum of affordable processor and memory technologies. This gives machinery manufacturers the potential to inexpensively push the control logic out of the terminal and back into the electronic control units, making the displays true thin clients and providing manufacturers much more display flexibility at a lower cost.

Here are 8 ways manufacturers can benefit from using smart devices in place of display terminals.

1. Leverage investments made by consumer electronics manufacturers

Industrial and off-highway vehicle manufacturers and their suppliers are simply not capable of matching pace with the investment and technical progression of the devices in the consumer electronic world. The level of investment and speed of technology deployed in consumer devices by companies like Apple and Samsung is simply not within the reach of industrial and off-highway equipment sectors.

Exacerbating this problem is the limited volumes in the off-highway and industrial spaces — they are only able to access these technologies after they become available in consumer devices, and we then still need to spend years achieving their introduction to a machine. This cycle leaves manufacturers lagging the curve of consumer display expectations by years while investing a lot of time and money into advanced display systems that feel substandard by the time they reach operators (when compared against the latest phone or tablet they carry).

One way of mitigating this problem is by pushing some display functions into mobile devices. Here, without any hardware development or integration investment, equipment manufacturers can leverage the hundreds of millions of R&D dollars put into consumer electronics, as well as the additional investments in the infrastructure that supports them. In this sense, by developing and deploying mobile applications that seamlessly connect with machinery, manufacturers get to leverage the latest in processing and display systems while minimizing investments.

2. Push display features into operator mobile devices

This requires some consideration for both security and safety strategies that vary from manufacturer to manufacturer. On one end of the spectrum, the mobile device can be used as a simple display. The device receives information from the machine over a wireless link. This information is then rendered into value-added real-time information for the operator to view on the phone or tablet display, including whatever visual or auditory alerts are needed by the operator.

On the other end of the spectrum, the mobile device is an interactive element of the machine control architecture. In this embodiment the operator can provide machine control inputs through the phone or tablet — whether that operator is within or outside of the machine’s cab.

And, of course, there are many hybrid models for the utilization of the mobile devices in interaction with off highway and industrial equipment where input capabilities through the mobile device are possible, but limited to a smaller set of functions.

3. Utilize app update infrastructure through Android, Apple, and other devices

Where delivery of a new embedded feature or capability might require a service bulletin, dealer notice, or integration with a new vehicle model year the deployment of complimentary mobile capabilities can be done in a matter of days and launched whenever may be convenient for a vehicle manufacturer.

When coupled with the ability to deliver ECU firmware through the mobile application interface, it becomes possible for vehicle manufacturers to perform significant update campaigns, verify which vehicles have been reached with those campaigns, and to do so without any telematic or dealer service expenses.

4. Break the dependence on vehicle model year release cycles

It has, traditionally, been very difficult to add value for customers of off-highway equipment out of cycle with a machine’s delivery. Should a competitor release a new feature in many circumstances we as an industry are relegated to waiting for the next machine cycle to deliver a competitive response. To the extent that there is mobile experience integrated with the usage of the machine, innovative features enabled through the mobile application can be deployed at any time giving manufacturers the potential to quickly deliver differentiable features out of sequence with machine model year cycles (and make those features available to both new and existing customers).

5. Leverage community to fuel development and growth

With a mobile application also comes the potential to leverage community to fuel development and growth. For example, if there is an industrial segment that is a relatively small consumer of machines but has a strong desire for a specific display, license can be extended by the equipment manufacturer to view and use the data output by the machine. In this manner, a supplier in a specific market segment can develop an application experience that is unique to that one market segment, providing a value added experience to operators in that segment without requiring any development investment, support, or maintenance from the vehicle manufacturer.

6. Rapidly deliver features / speeding to market

Embedded development can be comparatively time consuming and expensive when compared against mobile development. Embedded developers are generally more difficult to hire and train, the software more time consuming to develop and deploy, and the verification and validation activity associated therewith similarly nontrivial. In contrast, working against a defined embedded interface mobile software development is comparatively less expensive, developers more accessible, and software deployment more rapid.

7. Display cost reductions

To the extent that operators are bringing their own devices, and machine displays can become simpler and less expensive, this initiative offers the potential for cost reduction of the machine electrics while delivering more features to its operators.

8. Capture user and machine data

Utilization of a mobile application provides a broad spectrum of possibilities for the capture of both machine and operator data. For machines where telematic connectivity may not be possible, utilization of an application may provide the ability to cache and deliver valuable machine data to a manufacturer (in lieu of the cellular connectivity onboard the machine). The application can also acquire demographics about users, and information about how they navigate and use the application, that can provide user and usage statistics that can become a powerful force for informing future development activity that will help optimize equipment and interfaces for operators.

David Batcheller – President & CBO

David Batcheller – President & CBO

https://www.appareo.com/2020/11/25/8-benefits-of-using-tablets-as-displays-in-off-highway-and-industrial-machines/

What’s the difference between SIM and eSIM?

Connectivity technologies are confusing for people, and the industry is loaded with perplexing acronyms and buzzwords.

One of the most recent areas commonly fostering misconceptions is the difference between SIMs and eSIMs. This article is going to break it down in way that will hopefully help to inform your connectivity conversations.

Understanding SIMs The abbreviation SIM means “Subscriber Identity Module” and the devices were originally created to identify which subscriber is associated with a phone. Most people have a specific physical impression of a SIM, which is a little plastic card that we slide into a phone. In fact, there are a number of different physical manifestations of what you would know as a SIM card.

The abbreviation SIM means “Subscriber Identity Module” and the devices were originally created to identify which subscriber is associated with a phone. Most people have a specific physical impression of a SIM, which is a little plastic card that we slide into a phone. In fact, there are a number of different physical manifestations of what you would know as a SIM card.

The industry has different media on which a subscriber for a device can be identified. In general, manufacturers of rugged connectivity equipment strongly prefer and heavily leverage the MFF2 (M2M form factor). This is also sometimes referred to as a Machine Identification Module, or “MIM.” The reason manufacturers prefer these MFF2 units is because the vibratory specifications for aircraft and off-highway equipment are very unfriendly to SIM cards like the 3FF. During rigorous vibration tests, the shaking of the SIM card against its cage (which creates a phenomenon called fretting corrosion) wears through the very thin metal deposited on the plastic and destroys the card, resulting in the cellular function to stop working. Not cool.

eSIM vs SIM

Regardless of whether or not you have a 2FF, 3FF, 4FF, or MFF2 SIM/MIM, that hardware is really just a carrier for the UICC (universal integrated circuit card). This UICC is a read-only network profile. In other words, the device manufacturer will get a pile of chips (in any of the hardware manifestations shown above) that are pre-loaded with keys that cannot be changed during, or after, device manufacture.

Recently, it has become possible to purchase hardware that contains an eUICC (embedded universal integrated circuit card). This change means that instead of having a read-only network key on the SIM/MIMs that the manufacturers receive, this hardware can now be programmable and can host keys from multiple carriers on a single SIM/MIM. Some people initially think “great, I can tell AT&T to get lost and just program my unit over the air to work on Verizon whenever I want.” Unfortunately that isn’t true. Although that would be a great capability and introduce helpful flexibility for a lot of customers in many applications, you simply cannot do that today with an eUICC.

However, this is still really cool for manufacturers.

Here is why you should be excited about eSIM capabilities. Device manufacturers will often work with a carrier partner (e.g. AT&T, KPN, Rodgers, T-Mobile, Verizon, Vodafone, etc.) to certify a device with a specific carrier. Then, behind that carrier are dozens of local networks that will support these devices.

What the eSIM allows people to do is have multiple network profiles for local carriers on a single product, and update those over the air. When a vehicle travels from geography to another while using the same carrier, your device manufacturer can update the device to provision it for the local network, without changing a SIM. This is really powerful for getting products into geographies where cellular plan and regulatory constraints have historically driven a multitude of additional device SKUs and given manufacturers significant headaches managing equipment export — or equipment travel from one geography from another.

Some examples:

For equipment manufacturers, eSIMs are going to be a powerful tool for simplifying connectivity of a fleet while minimizing the burden on the manufacturer and reducing the number of device SKUs required to achieve truly global connectivity.

David Batcheller – President & CBO

David Batcheller – President & CBO

https://www.appareo.com/2020/10/08/whats-the-difference-between-sim-and-esim/

Appareo Releases New Telematics Gateway with 4G/3G/2G and U.S., EU, Brazilian, and Other Certifications Enabled by Onboard eSIM

NEWS RELEASE

Appareo Releases New Telematics Gateway with 4G/3G/2G and U.S., EU, Brazilian, and Other Certifications Enabled by Onboard eSIM

FARGO, North Dakota (August 20, 2020) — Appareo today released a new product in the company’s award-winning line of telematically-enabled electronic control units (ECUs). The Gateway 270 is a rugged IP67-rated edge computing platform for mobile equipment applications. This device is deployable in a broad range of North American, South American, and European markets, making it ideal for equipment manufacturers with broad geographic distribution.

Like other 200 series Appareo Gateways, this product contains an array of wired and wireless communication technologies, making it well suited for a broad spectrum of equipment control, monitoring, and connectivity challenges. The Gateway 270 contains Wi-Fi, Bluetooth, LTE (4G) cellular connectivity with 3G/2G fallback, BroadR-Reach, Ethernet, GPS, CAN, and RS-232 serial communications.

Gateway 270 is built on a popular distribution of embedded Linux (Yocto) with Docker support, allowing a convenient development environment for both developers to work on the Gateway using C++, C#, or other common development languages. This flexibility and approachability allows Appareo customers to use a variety of approaches and resources to achieve the maintenance, service, and operational benefits of a highly-capable telematics product.

“Appareo is really excited about this product and its broad geographical potential. Having three generations of cellular technology, coupled with the eSIM, and certified in historically challenging deployment geographies like Brazil will provide major logistic convenience and SKU simplification for our global customers,” said David Batcheller, President and CEO of Appareo.

To maximize the geographic potential of the Gateway 270 Appareo worked with carrier partners Vodafone International and TaTa Communications. The capabilities of Appareo’s carriers, coupled with Appareo’s Data Services Platform infrastructure, delivers convenient device and subscription management over web-based or API interfaces for management of a few—or a few thousand—connected vehicles.

To contact Appareo, acquire a development kit, and begin working with Appareo Gateways, visit appareo.com/gateways.

Appareo Gateway Series:

# # #

About Appareo

Appareo is a recognized leader in the custom design, development and manufacture of innovative electronic and software solutions for aerospace and terrestrial applications. Through the creative application of cutting-edge technologies, Appareo creates complex end-to-end solutions that include both mobile and cloud-based components. The company is privately held, with headquarters in Fargo, N.D., and a design office in Paris, France. All products are built and supported in the USA.

Product Photos

Download photos from our Online Media Kit.

https://www.appareo.com/2020/08/20/appareo-releases-new-telematics-gateway-with-4g-3g-2g-and-u-s-eu-brazilian-and-other-certifications-enabled-by-onboard-esim/

Appareo Releases Highly-Capable, Rugged Telematics Gateway with Truly Global Connectivity

NEWS RELEASE

Appareo Releases Highly-Capable, Rugged Telematics Gateway with Truly Global Connectivity

The new telematically-enabled ECU features Iridium® satellite connectivity along with LTE, Wi-Fi, Bluetooth, 433 MHz, CAN, BroadR-Reach, Ethernet, and GPS

FARGO, North Dakota (June 29, 2020) — Appareo today released a new product in the company’s award-winning line of telematically-enabled electronic control units (ECUs). The Gateway 360 is a rugged yet lightweight edge computing platform for mobile equipment applications that provides a wide range of communication technologies: Iridium SBD, Cellular, Wi-Fi, Bluetooth, and 433 MHz radios with, GPS, BroadR-Reach, Ethernet, and controller area networking (CAN). The device is built with an IP67-rated rugged enclosure for use outdoors and for mounting on heavy machinery.

The Appareo Gateway 360 is unique in that it couples truly global wide area connectivity capabilities through both an Iridium satellite connection, LTE connectivity with local area Wi-Fi, Bluetooth, and 433 MHz radios in a powerful computational platform capable of receiving and processing data from a wide range of vehicle networks and buses.

“The 300 series of Gateways are powerful edge computational products that provide a truly global connectivity solution capable of bridging the communication gap between all manner of on- and off-machine applications in very rugged environments,” said David Batcheller, President & CEO of Appareo. “The broad spectrum of communication technologies in the Gateway 360 offers an amazing array of solutions to global off-highway connectivity challenges.”

Off-highway machines are often used in very remote parts of the world. The cellular capabilities of the Gateway 360 are certified in dozens of countries; however, cellular coverage is limited in some geographies. Appareo’s use of the Iridium SBD transceiver allows for truly global machine coverage. The presence of Iridium on the device ensures that critical machine data can be retrieved, and wherever that equipment may be (land, air, or water) the Gateway 360 will keep Appareo customers and their machines connected.

The local area network connections (Wi-Fi, Bluetooth, and 433 MHz) allow machines to communicate directly with each other and with the operators or passengers. This allows people near the machine in its job site or field to be connected, informed, or in control, using real-time data with zero latency and no network costs. Further, groups of machines can communicate with machines and attachments to improve operator experience and efficiency.

For example, using 433 MHz or Bluetooth, the Gateway 360 can communicate with active RFID products, like the AT-40 asset tracker, tire pressure sensors, and other wireless machine sensors. This capability allows for machines to receive information from hydraulic and mechanical attachments, and despite the lack of electrical power on those attachments, use information from the active RFID tag to recognize the attachment, and automatically adjust machine control settings accordingly.

From remote diagnostics (securely accessing devices with available VPN remote access to troubleshoot equipment in real time) to inexpensively deploying firmware updates over the air through differential software updating tools, Appareo Gateways offer a wide spectrum of capabilities that go beyond traditional telematic data usage for preventive maintenance and remote support.

Appareo Gateway Series

Appareo and Iridium Communications Inc. (Nasdaq:IRDM) originally partnered in 2016 to release technology to equip motorized farm vehicles with terrestrial and satellite communication capabilities, enabled by the truly global Iridium satellite network — the only mobile voice and data satellite communications network that spans the entire globe. Appareo was one of the first companies chosen to integrate the Iridium 9603 chipset, the smallest commercial two-way satellite transceiver.

“Appareo continues to be a leader in bringing next generation telematics solutions and global connectivity to customers,” said Bryan Hartin, Executive Vice President, Sales and Marketing, Iridium. “With the Gateway 360’s truly global machine coverage, critical machine data can now be retrieved in even the most remote locations.”

AGCO Corporation (NYSE:AGCO) integrated Appareo’s 300 Series Gateways for its telematic solutions, specifically to expand wireless telemetry solutions for remote precision agriculture and machine monitoring.

“AGCO has been working with Appareo for many years and we have built our connectivity strategy leveraging the Gateway 360. We see advantages with the capabilities and the global reach this product provides, whether we are leveraging cellular or the Iridium satellite capabilities. It is great to have a partner that has deep expertise and is willing to work closely on our mutual goals,” said Seth Crawford, Vice President, Fuse Connected Services and Digital Customer Experience at AGCO.

To learn more about Appareo’s line of Gateways, visit appareo.com.

# # #

About Appareo

Appareo is a recognized leader in the custom design, development and manufacture of innovative electronic and software solutions for aerospace and terrestrial applications. Through the creative application of cutting-edge technologies, Appareo creates complex end-to-end solutions that include both mobile and cloud-based components. The company is privately held, with headquarters in Fargo, N.D., and a design office in Paris, France. All products are built and supported in the USA.

Product Photos

Download photos from our Online Media Kit.

https://www.appareo.com/2020/06/29/appareo-releases-highly-capable-rugged-telematics-gateway-with-truly-global-connectivity/

Appareo Releases New Product Line of Telematic and Connectivity Solutions for Aviation

NEWS RELEASE

Appareo Releases New Product Line of Telematic and Connectivity Solutions for Aviation

Conexus® Aircraft Communication Units are highly-capable, well-connected mobile computers for a broad range of aircraft types

FARGO, North Dakota (June 3, 2020) — Appareo today announced the release of a new product line of Conexus® Aircraft Communication Units (ACUs). These units are lightweight computing and communications devices that function as a data acquisition system for flight data monitoring (FDM) or flight operations quality assurance (FOQA) programs for fleet operators, or as a telematic and connectivity product for airframe manufacturers. The first product in this line, the ACU-200, is already being installed in multiple aircraft.

The ACU-200 can connect with aircraft systems, avionics, or engines using Ethernet, ARINC 429, or RS-422. The unit is qualified against RTCA DO-160G, and is designed with cybersecurity in mind. Additionally, the ACU-200 features very low power states, allowing Appareo customers to remotely connect to the unit and retrieve data even while the aircraft is powered down. The Conexus line is designed to be used in both fixed and rotary wing applications.

For airframe manufacturers, the Conexus ACU-200 is a helpful tool for monitoring the usage of aircraft in the fleet — providing valuable statistics to inform predictive maintenance scheduling, prediction of service work, and to improve depot and part distribution activities to ensure maximum customer uptime. For operators, the Conexus ACU-200 offers a single FDM/FOQA data recorder solution capable of being fit across a broad spectrum of aircraft in a mixed fleet, easing the challenges of integration and data offload logistics.

“FDM or FOQA programs are valuable for fleet operators to monitor trends, identify areas of risk, and deploy training programs to mitigate those risks. However, it can be a challenge for mixed-fleet operators to effectively analyze their flight data when it is collected in multiple acquisition systems” said David Batcheller, President & CEO of Appareo. “The ACU-200 is an ideal solution for those programs because it was designed for use in both modern and legacy aircraft,” Batcheller said.

Using the onboard inertial and GPS capabilities, the ACU-200 can provide an actionable volume of flight data from any kind of aircraft without needing to interface with avionic systems. For aircraft with digital buses available, the ACU-200 can acquire flight data directly from the aircraft system. This allows the ACU-200 to be implemented as a single avionic solution for a mixed fleet.

Additionally, while many flight data acquisition systems rely on physical means of transporting information (e.g., requiring operators to remove SD cards from their flight data recorders in order to transfer the data to a computer), Conexus products offer global 4G/3G/2G cellular data offload capabilities, ensuring the maximum speed of data reception while simplifying system maintenance and reducing costs.

The ACU-200 can be integrated with other Appareo products, such as the Vision 1000 to provide cockpit image and audio data for cellular offload, or with the RDM-300 to provide crash-hardened storage of the data acquired by the ACU-200.

“More than ever, the world recognizes the importance of making data work for us,” said Batcheller. “By developing the Conexus line of telematic and connectivity products that can perform alone or be integrated with our other flight data recording and storage solutions, Appareo is offering an approachable, expandable way for customers to access their data and put it to work.”

Find full product specifications on the ACU page, or contact Appareo for information about pricing.

About Appareo

Founded in 2003, Appareo pioneered FDM for light fixed-wing aircraft and rotorcraft by producing the most compact and lightweight flight data recorder available. Currently, multiple airframe manufacturers utilize Appareo data recording products as standard equipment on their aircraft. Appareo’s accompanying FOQA software suite was named “Product Breakthrough of the Year” by Aviation Week & Space Technology in 2007. Appareo then became the industry leader in the design and production of ADS-B equipment for general aviation, after introducing the first StratusTM portable ADS-B receiver in 2012, and subsequently introducing a series of certified and non-certified Stratus products designed to advance situational awareness and safety, increase pilot comfort, reduce pilot workload, and improve the flying experience for aviators.

Appareo is a recognized leader in the custom design, development and manufacture of innovative electronic and software solutions for aerospace. Through the creative application of cutting-edge technologies, Appareo creates complex end-to-end solutions that include both mobile and cloud-based components. The company is privately held, with headquarters in Fargo, N.D., and design offices in Tempe, Ariz. and Paris, France. All products are built and supported in the USA.

# # #

Conexus and Stratus are registered trademarks of Appareo Systems, LLC. ©2020

https://www.appareo.com/2020/06/03/appareo-releases-new-product-line-of-telematic-and-connectivity-solutions-for-aviation/

Appareo Releases Highly-Capable Rugged LTE Telematics Gateway with 6 CAN Busses, Wi-Fi, Bluetooth, BroadR-Reach, Ethernet, and GPS

NEWS RELEASE

Appareo Releases Highly-Capable Rugged LTE Telematics Gateway with 6 CAN Busses, Wi-Fi, Bluetooth, BroadR-Reach, Ethernet, and GPS

FARGO, North Dakota (May 27, 2020) — Appareo today released a new product in the company’s award-winning line of telematically-enabled electronic control units (ECUs). The Gateway 260 is a rugged yet lightweight edge computing platform for mobile equipment applications that provides a wide range of communication technologies: Wi-Fi, Bluetooth, Cellular, GPS, BroadR-Reach, Ethernet, and controller area networking (CAN). The device is built with an IP67-rated rugged enclosure for use outdoors and for mounting on heavy machinery, and like all Appareo Gateways, the Gateway 260 is built on a popular distribution of embedded Linux (Yocto) with Docker support that allows developers to quickly deploy applications.

The Appareo Gateway 260 is unique in that it couples the capabilities of a modern LTE connectivity device and a powerful computational platform capable of receiving and processing data from a wide range of vehicle networks and buses.

“While other solutions require multiple, separate devices to accomplish computation and cloud connectivity, Gateway 260 was designed to aggregate local/wired communications and Wi-Fi/cellular connectivity in one box with powerful processing capabilities, lowering the total cost for our customers,” said David Batcheller, President & CEO of Appareo. “Our architecture that enables strong local area network integration between off-highway equipment and mobile devices like phones and tablets continues in the Gateway 260. This allows our customers to create mobile app experiences that control or monitor their machines using the operator’s portable electronic devices.”

For example, Väderstad and Appareo collaborated to design an entirely new machine control architecture for Väderstad planters and seeders, uniquely featuring the capability to control the machine using iPads through a Wi-Fi interface. The Appareo Gateway acts as the server for the user interface, contains all the control logic necessary to operate the machine, and commands other ECUs on the CAN bus to execute machine tasks or get information. The user has the ability to utilize an ISOBUS-compatible Virtual Terminal, an iPad display, or both at the same time. With the inclusion of an iPad as a control interface, the user is able to perform all functions wirelessly to the machine, which has made out-of-cab operations much more convenient. Väderstad was the first agricultural machinery manufacturer to utilize a mobile tablet in this way.

From remote diagnostics (securely accessing devices to troubleshoot equipment in real time) to inexpensively deploying firmware updates through differential software updating tools, Appareo Gateways offer a wide spectrum of capabilities.

One company that integrated Appareo’s 300 Series Gateways for its telematic solutions is AGCO Corporation (NYSE:AGCO). AGCO utilized an Appareo 300 Series Gateway with Iridium (Nasdaq:IRDM) connectivity to expand AgCommand, AGCO’s complete, end-to-end, wireless telemetry solution for remote precision agriculture and machine monitoring. Appareo is one of only a few integrators in the world for the 9603 Iridium chipset — the smallest commercial two-way satellite transceiver — which enabled AGCO to become the first in agriculture to equip machines with connectivity on a broad, global scale. The Appareo Gateway can collect and distribute real-time data, product and performance data, health and asset management data, location data, security and recovery data, in addition to remote diagnostics and the possibility for future predictive maintenance capabilities.

To learn more about Appareo’s line of Gateways, visit www.appareo.com/products/highly-capable-telematic-products/.

# # #

https://www.appareo.com/2020/05/27/appareo-releases-highly-capable-rugged-lte-telematics-gateway-with-6-can-busses-wi-fi-bluetooth-broadr-reach-ethernet-and-gps/